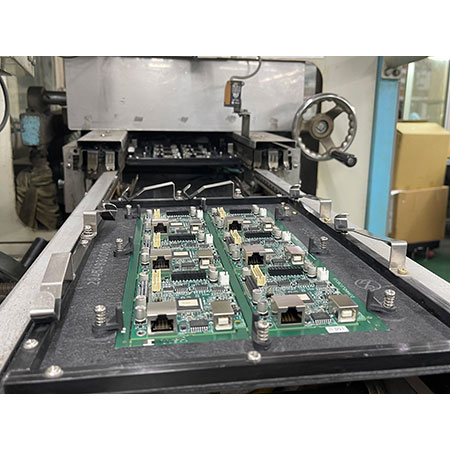

SMT PCB Assembly Process

We are a technical Taiwan SMT PCB Assembly Process manufacturer, factory, supplier and exporter. Depending on stable investment, superior competence and good after-sale service, we have made us as one of the leading manufacturers and exporters in the industry. We promise quality products and competitive price and on-time delivery for you. We have been establishing long-term business with our customers. If you are interested in any model of our products, please be free to contact us.

Our expertise has enable us to ensure finest

SMT PCB Assembly Process

by subjecting our products to stringent quality control measures during each stage of production and while dispatch. We sincerely welcome all relevant friends all over the world to come for visit and cooperation!SMT PCB Assembly Process

Model - 3-2

DIP production line equipment

DIP Production Line and Capacity

Line : DIP Line 1, Model HD-LF310SIWD, Lead-free plug-in production line is 9 meters (With spray type no-cleaning and hot air preheating)

Line : DIP Line 2, Model HD-LF310SIWD, Lead-free plug-in production line is 6 meters (With spray type no-cleaning and hot air preheating)

Line :DIP Line 3 , The back repair production line is 15 meters long

Selective Soldering Machine*1

DIP Production Line and Capacity

Line : DIP Line 1, Model HD-LF310SIWD, Lead-free plug-in production line is 9 meters (With spray type no-cleaning and hot air preheating)

Line : DIP Line 2, Model HD-LF310SIWD, Lead-free plug-in production line is 6 meters (With spray type no-cleaning and hot air preheating)

Line :DIP Line 3 , The back repair production line is 15 meters long

Selective Soldering Machine*1

Enquiry Now

Products List

Selective Soldering Machine

Use the characteristics of the small tin furnace nozzle to move easily, fix the circuit board to be soldered on the frame, and use the solder liquid in the small tin furnace to move to the solder feet that touch the parts to achieve the welding effect

No special fixtures or oven trays are required when using selective soldering furnaces

Due to the small contact area, the circuit board is not easy to bend and deform during processing

The tin-eating effect of parts through holes is good, and good welding quality can be obtained

oven

After a period of time after the PCB is produced, it will absorb moisture in the environment, which will easily cause the PCB to explode or delaminate during the production process.

As the temperature rises, the volume of water molecules will expand rapidly. The temperature of the soldering equipment continues to rise, and the PCB or parts cannot release water vapor, which is easy to cause deformation and damage. The main purpose of baking PCBs and components is to dry moisture-absorbing components, so as to Avoid deformation in the furnace

The oven has different temperature and time settings for different parts and packages during baking, and a reasonable parameter value must be set

Lead-free double wave tin furnace

Lead-free dual-wave solder bath with special runner and nozzle adjustable design, specially designed for lead-free DIP process, solder bath made of titanium alloy, stainless steel sleeve heating device, PID temperature control.

The tin wave nozzle is an adjustable nozzle specially designed for the lead-free process, which is easy to adjust, and the jet flow height can reach up to 12mm, which can penetrate the lead-free PCB parts, reduce empty soldering and short circuit phenomena, and achieve perfect soldering.

The conveying track is equipped with a torque limiter to protect the PCB and the conveying mechanism.

The preheating zone is a sealed three-stage control length of 1.8 meters, all of which are imported quartz tubes for heating, and hot air preheating zone can be selected, the thermal compensation is rapid and stable, and it is covered with heat-resistant tempered glass, which has high safety.

The temperature control is all digital setting, SSR+PID automatic control.

Dimension: L4000*W1300*H1700mm

PCB Width: Max310mm

Solder Tank: 0℃~400℃

Inject Height :0~20mm

English

English Français

Français Deutsch

Deutsch Русский

Русский Português

Português Italiano

Italiano हिन्दी

हिन्दी Español

Español Nederlandse

Nederlandse العربية

العربية Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Bahasa Indonesia

Bahasa Indonesia বাঙ্গালী

বাঙ্গালী Türk

Türk 繁體中文

繁體中文