GERSHIN ELECTRONICS CO., LTD. is recognized as a world class manufacturer, supplier and provider of SMT Soldering. As one of the most experienced manufacturers in the business. We always supply our customers with lowest-failure-rate, fast lead-time, cost -effectiveness, and best after-sales service. We have been established trade relation with many countries around the world, our company has employed a professional and growing team for research and development. to our capability of logic design, OEM/ ODM are mostly welcome. We are acknowledged by the best service to its customers, by good quality, reasonable price and prompt delivery.

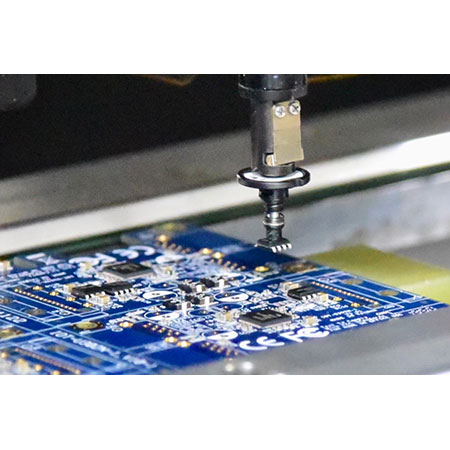

SMT Soldering

SMT production line

All SMT production lines are nitrogen reflow manufacturing. Three of which are high-speed production lines; Two are medium-speed production lines.

SMT production accuracy is +/- 0.025 ~ 0.040 mm for CHIP products; It is +/- 0.025 mm for Integrated Circuit (IC) products.

The maximum size of PCB produced by the SMT production line is 1400 mm * 510 mm. Applicable part size is 0.4 mm * 0.2 mm (Imperial Code No. 01005) or above. Fine pitch for QFP should be greater than 0.3 mm; Ball diameter for BGA should be greater than 0.2 mm; Size for CSP should be greater than 0.2 mm.

SMT Production Line and Capacity

The daily capacity of SMT production line is an estimation based on the safety production hours of 20 hours/day when manufacturing Resistor/Capacitor products.

SMT Line 1--------Yamaha Σ-G5S + M20----------------- Capacity 1,200,000

SMT Line 2--------Yamaha M10 (*2) + M20------------------Capacity 900,000

SMT Line 3------- Yamaha M10+Σ-G5S + S10 + M20----Capacity 1,800,000

SMT Line 4--------Yamaha Σ-G5S + M10 + M20---------Capacity 1,500,000

SMT Line 5--------Yamaha S10 + S10-------------------------Capacity 800,000

Automatic solder paste screen printer

Convection Reflow(Model HD-LF HACRF) Nitrogen

Steel plate washer

SMT production line- Automatic solder paste screen printer

Printing of solder paste is an important part of PCB processing. It is necessary to accurately apply solder paste to the required position of the circuit board and control the amount of solder paste. Therefore, a steel plate is used to control the printing of solder paste.

The production line adopts a fully automatic solder paste printing machine, which is suitable for mass production. During production, it can automatically feed the board, automatically align, and automatically print solder paste. After completing the solder paste printing operation, it will automatically send out the circuit board. This can provide high Precision and high stability of solder paste printing quality, reducing the chance of bad solder paste printing

LEAD-FREE CMA HOT AIR REFLOW MACHINE

Mode : YX-LFHACRF

Conveyor : Chain & Belt

Direction: L→R, R→L

Speed 0-2M/min

PCB Width: track:350mm, Metal mesh belt:400mm

Tp. Control: SSR+PID

Tp. Range: 0℃~400℃

Air Speed :Digital speed setting

Compensation: Steady current storage device

Dimension : 5100*1450*1460mm(L*W*H)

Operate High : 900mm±20mm

The chain rail conveying is highlighted by a 3-axle positioning and subject to specific refractory processing for smooth movement of the two parallel rails.

We're constantly looking for new ways to improve the way we work and pass the savings on to you. That's why we've been working closely with suppliers to ensure we have

English

English Français

Français Deutsch

Deutsch Русский

Русский Português

Português Italiano

Italiano हिन्दी

हिन्दी Español

Español Nederlandse

Nederlandse العربية

العربية Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Bahasa Indonesia

Bahasa Indonesia বাঙ্গালী

বাঙ্গালী Türk

Türk 繁體中文

繁體中文